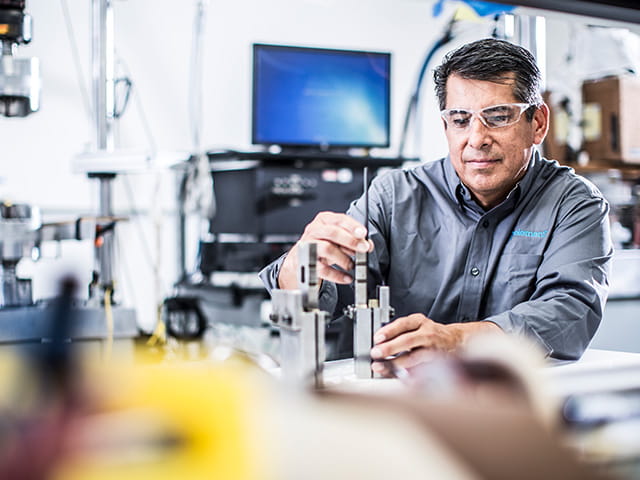

Element is the largest, independent provider ofmaterials testingservices to the global Aerospace sector.

We work in close partnership with all of the Aerospace Primes and their supply chain partners to help them develop better materials to support the drive for lighter, more fuel efficient aircraft; to help them get them to market on time; save them time and money through efficiency improvements; and to minimize the risk to their business through all of their materials development activities.

Element has over 80 years’ experience in both commercial and military aerospace testing and dedicate more than 3,000 technicians, engineers and scientists dedicated to the sector. When combined with our 29 Nadcap accredited laboratories, with 41 different Nadcap accreditations, and many Aerospace customer approvals, we have an international capability, footprint and geographic reach that is unrivaled in the Aerospace Testing, Inspection andyabo官网入口industry.

Everything we do is designed to help our customers to make certain that products and services they deliver are always safe, quality, compliant and fit for purpose.

Our services

Element has one of the most comprehensive range of materials testing services for the aerospace sector. Click on one of the links below to find out more

Mechanical Testing

Find out about Element's tensile, elongation, compression, impact, fracture toughness, stress, rupture, fatigue, hardness, abrasion & wear, bend, pressure, shear and torque testing services.

Read More

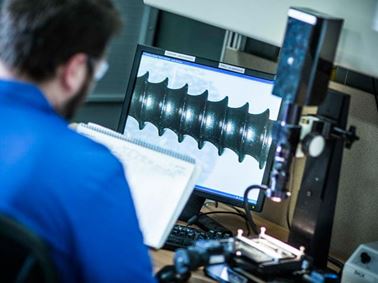

Non-Destructive Testing

Find out about the range of NDT services Element uses to evaluate the properties of a material, parts, products, welds, or systems without materially affecting the integrity of the items being tested.

read More

Structures

Find out how Element test key structures within aircraft, under static and dynamic operational loads, to assess the impact of fatigue and to determine accurate in-service life predictions for these structures.

Read More

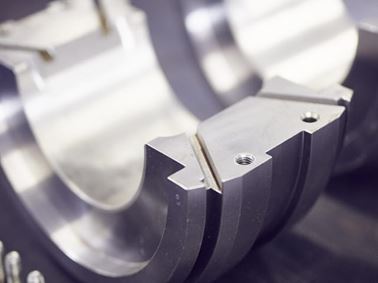

Metallurgical Testing

Find out about Element's range of metallurgical testing services, including microscopy, corrosion evaluation, hardness and on-site services.

Read More

Fatigue Testing

Element's laboratories help customers characterize the properties and behaviors of materials and components using varying loads, speeds, and environmental conditions to create predictive patterns of future behavior.

Read More

Tensile Testing

Element delivers industry-leading tensile testing services for a wide range of metallic, polymeric, and other advanced materials to the Aerospace and other industry sectors.

Read More

Hardness Testing

Element's laboratories use a variety of micro-indentation and macro-indentation testing methods to determine the hardness of a material to deformation.

Read More

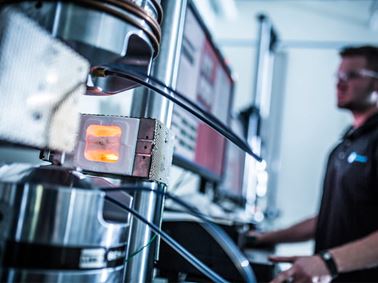

Stress Rupture and Creep

Find out how Element uses a variety of stress rupture and creep test methods to assess the effect of long term stress on metals, composites and a range of other advanced materials.

Read More

紧固件

Find out how Element tests individual fasteners and fastening systems in high volumes, with reliable results to consistently meet the exacting demands of the Aerospace sector.

Read More

Additive Manufacturing

Find out how Element are leading the way in creating reliable and repeatable new test programs that deliver accurate results for the early adopters of additive manufacturing in Aerospace and other leading industry sectors.

Read More

Polymer Testing

We offer world-class materials expertise in polymers, elastomers, thermoplastics, composites and structural adhesives.

Read more

Impact testing

Find out about the complete range of impact testing services that area available from Elements worldwide network of Aerospace accredited laboratories

Read More

Ceramic Matrix Composites (CMC) Testing

Our aerospace testing experts help companies characterize their CMC materials and develop their products with the properties needed for lightweight and extreme high-temperature applications.

Read More

Chemical Analysis

Find out how Element's chemistry teams work with our customers to identify the contents, composition and quality of materials they develop and manufacture.

Read More