Carbon capture and storage is a relatively new technology to store pressurized carbon dioxide underground. One of the challenges is to keep pipelines and injection tubes safe and prevent corrosion. Element supports corrosion testing of metallic components and examines polymeric materials to reduce transport costs and avoid failure.

With the increased concern of carbon dioxide (CO2) on the environment, reducing carbon emissions into the atmosphere is now a major focus for most industrialized countries. Reducing carbon emissions has led to carbon capture and storage (CCS), or carbon capture, utilization and storage (CCUS) projects. The projects have predominately been in the USA and Canada for Enhanced Oil Recovery (EOR), but there is a growing demand in Europe, Asia and the Middle East.

Numerous global projects in the planning stage are operational as pilot, research, and development plants in most countries where CO2 is produced. Most CCS/CCUS projects aim to capture CO2 and store it below the surface, mainly in offshore locations.

Corrosion of CCS transportation pipelines

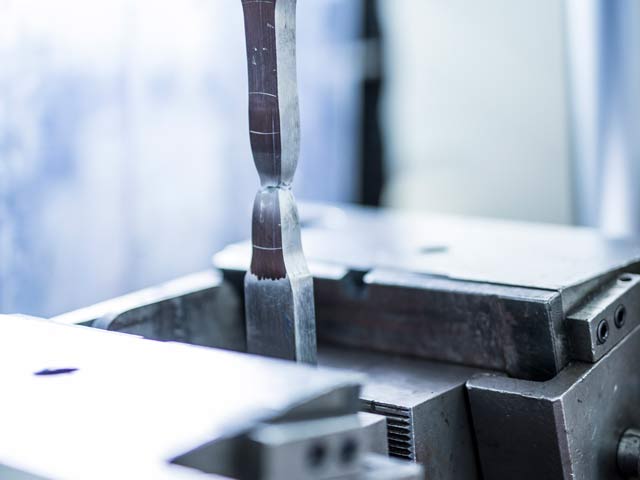

For metals used in the CCS/CCUS infrastructure, the corrosion or cracking of the carbon steel transportation pipelines and carbon steel or corrosion resistant alloy (CRA) injection tubing is the primary concern of potentially corrosive environment.

腐蚀的风险/需要evaluat开裂ed on a case-by-case basis since it’s severity will depend on the material and the specific levels of H2O, O2 and acidic gas impurities of CO, H2S, SOx, and NOx in the dense phase CO2.

In order to mitigate carbon steel corrosion in CCS transport pipelines, the use ofcorrosion inhibitorscan be considered. However, their effectiveness would be dependent on the specific conditions, so would require qualification testing.

Corrosion Testing for CCS infrastructure may be required to evaluate the resistance of the materials to:

- CO inducedStress Corrosion Cracking (SCC)of carbon steels (Transportation pipelines)

- H2S inducedSulfide Stress cracking (SSC)of carbon steels (Transportation pipelines)

- H2S induced Stress Corrosion Cracking of CRA’s (Injection tubing/casing)

- General corrosionof carbon steels (Transportation pipelines)

- Pitting corrosionof corrosion-resistant alloys-CRA’s (Injection tubing/casing)

Testing polymeric materials

The main concerns in the use of polymeric materials for seals, linings, etc. in the CCUS infrastructure are:

- the physical effects of the CO2 on those materials, for example swelling and weakening

- rapid gas decompression damage such as blistering, cracking, splitting

- 抗化学腐蚀气体杂质——我nfluence of contaminants on the long term integrity of the materials

- the high pressure and low temperature operating conditions for CCUS can be a limiting factor to the use of some polymers

- loss of product or environmental issues caused by permeation of CO2 through polymeric seals and liners

The Element advantage

Our centers of excellence for the Energy sector are located in the US and Europe. The locations are fully equipped to perform corrosion testing and electrochemical testing on metallic components and polymeric materials used for CCS/CCUS infrastructure.

For more information about our corrosion testing services for CCS/CCUS, or request a quote,contact ustoday.

Corrosion Services

Find out about Elements extensive corrosion testing expertise in the Oil & Gas industry across a global network of laboratories.

Read More

Structural Testing & Mechanical Engineering

Element offers a range of advanced and application oriented engineering services to help solve a wide variety of mechanical engineering and structural engineering analysis problems.

READ MORE

Coatings Testing

Find out about Elements range of coatings testing services designed to help to make certain that materials, products and pipelines we test for our customers are protected from corrosion, ultraviolet light, water penetration, heat, abrasion and chemicals.

read More

Materials Testing

Find out more about Element's comprehensive ranges of materials testing services available in the TIC sector, covering materials selection, application and performance testing as well as failure analysis testing services.

Read More