X-Ray Fluorescence (XRF) analysis is a simple, highly accurate test method used to determine a material’s chemical composition. Element’schemical analysisexperts are ready to provide you with precise data regarding the properties of your materials.

XRF testing uses a device to inundate the sample with a high energy primary x-ray beam. The irradiated sample emits secondary x-ray photons characteristic to energy or wavelength of elements present in the sample. The instrument detectors then count the emitted photons dispersed by selected crystals and identify and quantify the elements present.

XRF is a popular analytical tool because of its non-destructive nature, the ability to test materials with little or no preparation required, as well as being suitable for solid, liquid, or powdered samples.

Portable XRF testing services

根据项目需求,测试performed on-site as well as in our laboratories. When performed on-site, a handheld analyzer shoots a beam at the material, which sends feedback to a portable machine that generates a readout of the types and amounts of elements in a material.

Element’s portable XRF testing reports on a wide range of metals, including trace elements and major constituents. Results from this method are almost immediate, making it a very efficient way to check structures or individual pieces.

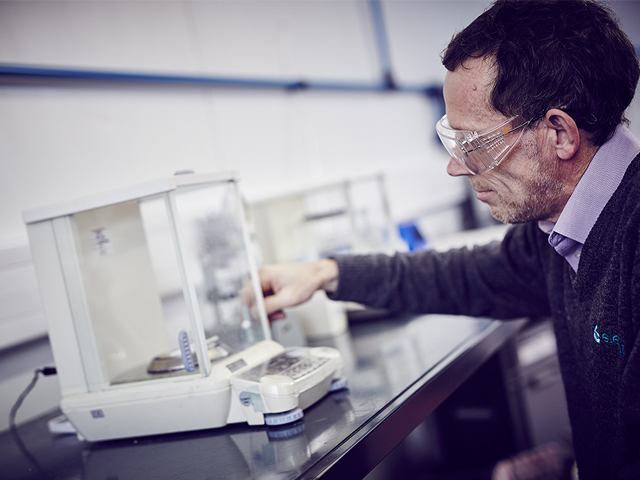

Laboratory XRF testing services

Our in-laboratory XRF uses a more sophisticated analyzer. With this method, samples need to be the appropriate size to fit the dimensional requirements of the equipment. Rather than being tested in the open air, the material is loaded into a vacuum chamber and irradiated.

While in-laboratory XRF testing takes longer than field analysis, it covers a broader range of elements and provides more detailed results. This method is generally preferred when a more accurate and thorough analysis of multiple elements is required.

Working with Element

Element performs XRF analysis for customers across the US, the UK, and Europe. Our chemical analysis experts work diligently to help you meet requirements and objectives quickly and provide certainty of the composition of your product.

For more information about our XRF testing services or to request a quote,contact ustoday.

providing certainty for nearly 190 years

More from Element

Services

Chemical Analysis

Find out how Element's chemistry teams work with our customers to identify the contents, composition and quality of materials they develop and manufacture.

Read More

SERVICE

X-Ray Diffraction (XRD) Analysis

Our engaged experts can review a variety of specifications and procedures, and help determine how x-ray diffraction can make your project a success.

Read More

SERVICES

Metallurgical Testing

Find out more about our metallurgical testing expertise and our comprehensive range services, from grain size analysis to fractography.

Read More

resource

亚慱体育怎么下载

发现blog posts, articles, white papers, webinars, and advice from our world-leading testing, inspection, and certification experts.

Our capabilities

Our Materials Testing Services

Abrasion and Wear Testing

Aerospace Fasteners

Aircraft Interiors Flammability Testing

Chemical Analysis

Chemical Processing

Composite Testing

Computed Tomography

Contamination Testing

Corrosion Testing

Die Steel Qualification

Differential Scanning Calorimetry (DSC)

Dynamic Mechanical Analysis

Eddy Current Inspection

Etching

Expert Witness Services

Failure Analysis

Fastener Testing

Fatigue Testing

FEA

Foam Testing

FTIR

Fractography Services

Fracture Toughness

Fuels and Lubricants Testing

Hardness Testing

Impact

Liquid Penetrant Inspection

Magnetic Particle

Material Properties

Mechanical Testing

Metallurgical Testing

NDT Field Services

Nondestructive Testing and Inspection

Nonmetals Failure Analysis

Nonmetal Mechanical Testing

Nonmetal Testing

On-site metallographic examination

Paint and Coating Material Testing Services

Passivation

Polymer Matrix Composite Testing

Polymer Testing Services

Positive Material Identification

Radiographic Inspection

Residual Stress Measurement

Residue Analysis

Sour Service Corrosion Testing

Stress Rupture and Creep Testing

Stress Strain Analysis

Tensile Testing

Thermogravimetric Analysis (TGA)