Element helps material manufacturers and product designers in the aerospace, automotive, and renewable energy sectors to evaluate material properties in flexural mode by providing three-point and four-point bend testing.

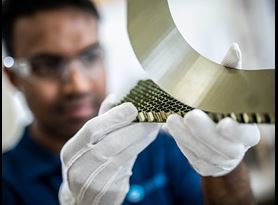

Flexural test for composite materials

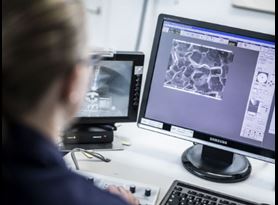

Bend testing incompositesis used to determine flexural strength and stiffness of a solid laminate or sandwich construction. The specimen is loaded in a horizontal position in a three-point or four-point loading configuration in a flexural test. The test fixture has a support point near each edge of the beam and a loading nose with one (third-point loading) or two (four-point loading) configurations. The distance between supports, and the loading points in the four-point configuration, can be easily modified to adapt the fixture to different specimen geometries and thickness-to-length ratios.

Flexural is a combination of three properties:

- Tensile

- Compression

- 剪切

The specimen in flexure will fail once one of the three basic stresses reaches its limiting value. The test result can help to understand the failure mode of a given geometry and loading configuration.

The Element advantage

Element’s experts provide Testing to ASTM, ISO, and EN standards for solid laminates and sandwich constructions to ensure the materials and products we test are safe and fit-for-purpose.Get in touchfor further information flexural testing of composite materials.

making certain for nearly 190 years

More from Element

Composites Testing

Find out how Element helps its customers to develop, test and qualify their composite materials to ensure that these complex, cutting-edge materials are safe, quality, compliant and ultimately fit for purpose.

Read More

Composite Damage Tolerance Testing

Element offers a variety of test methods that provide manufacturers with more insight into their composite materials’ damage tolerance and resistance.

Read More

Composite Raw Material Testing

Element’s composite raw material testing helps manufacturers understand the physical, thermal, and mechanical properties of the constituents used to create their composite product.

Read More

Structural Testing of Composite Components

Element’s composites experts will address composite testing in the Aerospace sector and describe how this can be applied to the Automotive, Wind Energy, Medical, Railway, and Oil and Gas industry for product validations.

WATCH NOW