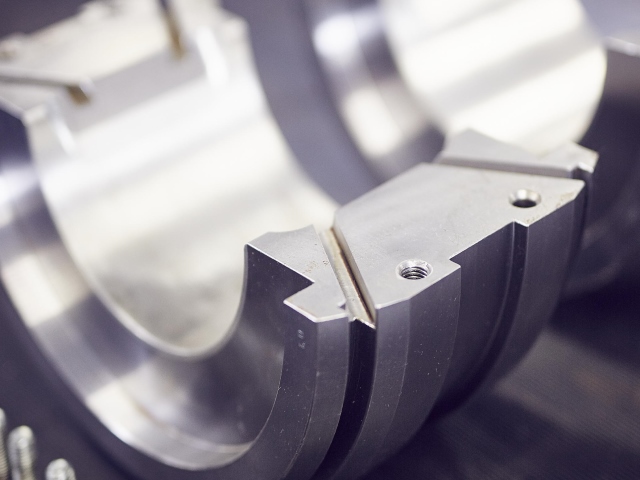

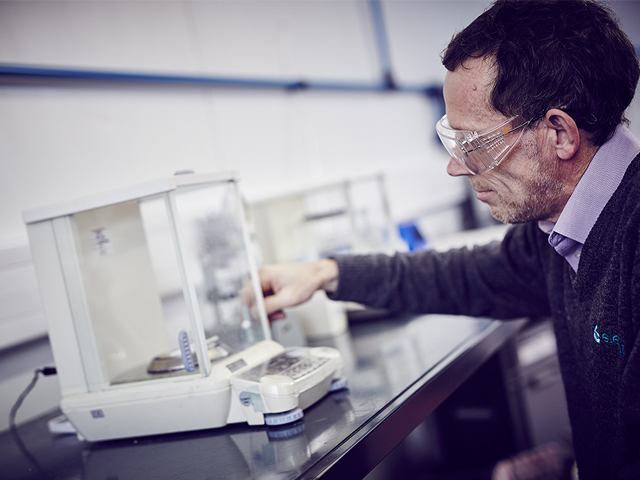

Metallurgical testing is used in virtually every industry and covers a wide range of services, from grain size analysis to fractography. Our Engaged Experts can identify material type, defects and processing errors using a variety of techniques and equipment.

Manufacturers are employing better technology to bring innovative materials to the market. While many traditional metallurgical testing methods used for evaluating metals remain the same, metallurgists are facing more challenges than ever before.

冶金测试集中于与定量结合金属的特性机械测试and化学分析。金相经常被用来确定材料类型,等级或晶粒尺寸,并提供新的材料或混合批次,微观结构分析和故障分析认证。yabo官网入口

Our metallurgical testing capabilities

Element’s metallurgical testing laboratories use the required expertise and technology to test both traditional metals and advanced alloys. Many of our metallurgical test methods can be done on-site, or alongside our experts in one of our state-of-the-art labs.

我们训练有素的冶金学家在:

- Corrosion

- Fractography

- 材料鉴别

- 宏观评价

- Microscopic evaluation

- 焊接测试

随着全球冶金测试地点,我们可以帮助任何项目,无论多大。有关我们的冶金测试服务或要求引用的更多信息,今天联系我们。

making certain for nearly 190 years

更多来自元

Services

Chemical Analysis

了解元素的化学团队如何与客户合作,以确定他们开发和制造的材料的内容,组成和质量。yabo娱乐vip

Read More

Services

Failure Evaluation

元素提供了全面的功能,以帮助确定失败的根本原因。

Read More

资源

亚慱体育怎么下载

发现博客、文章、白皮书,webinars, and advice from our world-leading testing, inspection, and certification experts.

Read More

我们在哪里

Element Locations

Learn more about our laboratories - where they are located; the unique capabilities they have and how they can help you solve your technical and commercial challenges.

FIND A LABORATORY

Our capabilities

Our Materials Testing Services

磨损磨损试验

Aerospace Fasteners

Aircraft Interiors Flammability Testing

Chemical Analysis

Chemical Processing

复合试验

Computed Tomography

Contamination Testing

腐蚀测试

Die Steel Qualification

差分扫描量热法(DSC)

动态机械分析

涡流探伤

Etching

Expert Witness Services

故障分析

Fastener Testing

Fatigue Testing

FEA.

泡沫测试

FTIR

断口服务

Fracture Toughness

Fuels and Lubricants Testing

Hardness Testing

影响

Liquid Penetrant Inspection

Magnetic Particle

Material Properties

Mechanical Testing

Metallurgical Testing

NDT Field Services

无损检测和检查

非金属故障分析

Nonmetal Mechanical Testing

Nonmetal Testing

On-site metallographic examination

涂料及涂层材料测试服务

钝化

Polymer Matrix Composite Testing

高分子材料测试服务

Positive Material Identification

Radiographic Inspection

残余应力测量

残留分析

Sour Service Corrosion Testing

Stress Rupture and Creep Testing

Stress Strain Analysis

Tensile Testing

Thermogravimetric Analysis (TGA)