As the use ofadditive manufacturingbecomes prevalent across industries, manufacturers are challenged to identify and understand the properties of their materials. Our powder characterization services are the first step to make certain your materials are fit-for-purpose, no matter their application.

Metal additive manufacturing offers a new landscape of complex component design for industries, including aerospace, transportation, and medical device. Metal powders provide many benefits when compared to traditional metal forging. Manufacturers can print the part exactly as intended, which requires no machining, less material waste, and the powder left over after printing can be reused.

Element’s powder characterization services

Our materials experts are at the forefront of additive manufacturing testing, providing comprehensive services from powder characterization to mechanical testing to failure analysis. We work to ensure your materials meet relevant standards, as well as any custom standards or test requests provided by your organization.

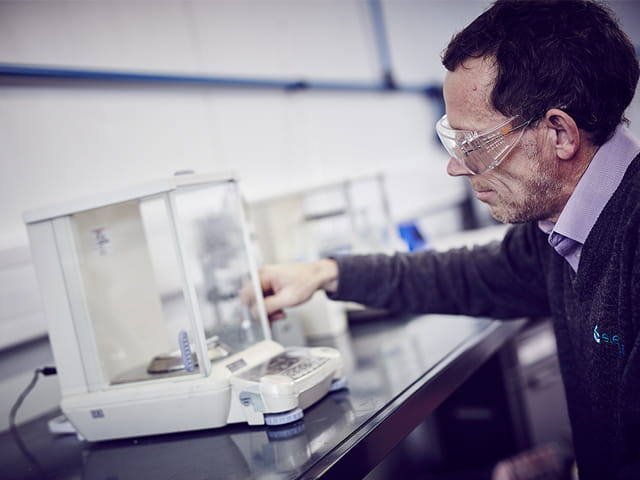

Powder characterization validates that the properties of the material are pure, uniform between batches, and ready to be 3D printed. Our powder characterization services include:

- Flow rate

- Apparent, tap and skeleton density

- Particle size distribution

- Particle form and shape

- Sieve analysis

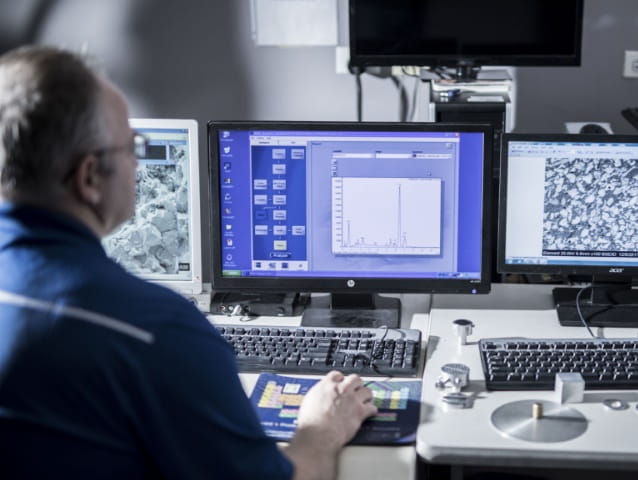

- SEM imaging

- 化学作用cal analysis

Element also provides chemical analysis, hardness testing,拉伸试验, fatigue testing, and more to ensure crucial material properties weren’t lost in the printing process and to understand the strength and durability of the final product.

To learn more about our powder characterization services or to request a quote,contact ustoday.

making certain for nearly 190 years

更多来自元素

Additive Manufacturing

Element's Engaged Experts provide the most comprehensive level of additive manufacturing testing services in the materials testing sector.

Read More

化学分析

Find out how Element's chemistry teams work with our customers to identify the contents, composition and quality of materials they develop and manufacture.

Read More

Evaluation Methods for 3D Printed Implants

Compared to traditional materials, additive manufactured materials require qualifying and validating of the powders, structures, individual printers and overall design, creating additional steps for characterization.

Read More

DMLS vs SLM 3D Printing for Metal Manufacturing

The techniques used to carry out the additive manufacture of metals are slightly different from those used to print plastics. The two main techniques are direct metal laser sintering and selective laser melting.

Read More

我们的能力

Our Materials Testing Services

Abrasion and Wear Testing

Aerospace Fasteners

Aircraft Interiors Flammability Testing

化学分析

化学作用cal Processing

Composite Testing

Computed Tomography

Contamination Testing

Corrosion Testing

Die Steel Qualification

Differential Scanning Calorimetry (DSC)

Dynamic Mechanical Analysis

Eddy Current Inspection

Etching

Expert Witness Services

Failure Analysis

Fastener Testing

Fatigue Testing

FEA

泡沫测试

FTIR

Fractography Services

Fracture Toughness

Fuels and Lubricants Testing

Hardness Testing

Impact

Liquid Penetrant Inspection

Magnetic Particle

Material Properties

Mechanical Testing

Metallurgical Testing

NDT Field Services

Nondestructive Testing and Inspection

Nonmetals Failure Analysis

Nonmetal Mechanical Testing

Nonmetal Testing

On-site metallographic examination

Paint and Coating Material Testing Services

Passivation

Polymer Matrix Composite Testing

Polymer Testing Services

Positive Material Identification

Radiographic Inspection

Residual Stress Measurement

残留分析

Sour Service Corrosion Testing

Stress Rupture and Creep Testing

Stress Strain Analysis

Tensile Testing

Thermogravimetric Analysis (TGA)