Article

What is Mechanical Testing and Why is it Important throughout the Product Lifecycle?

经过:MALC PERRY,MENG,应用销售工程师/高级冶金专家

Barry Ward Beng(Hons),Ceng,MIMMM,技术总监

机械测试是任何设计和制造过程的标准和基本部分。无论是表征材料的特性还是为最终产品提供验证,确保安全是所有机械测试的首要任务。测试在确保经济高效的设计以及技术进步和优越性方面也起着至关重要的作用。yabo娱乐vip

测试要求的起源

The test methodologies required are characteristically specified on drawings of the parts, which means that the testing responsibility falls to the manufacturer contracted for that part.

测试要求并非总是由管理机构制定的;经验丰富的设计和制造团队也了解测试的价值,以验证模型,进行改进,并提高零件的整体质量。当面对测试的成本和时间影响时,这个过程似乎很昂贵。然而,当涉及到降低成本时,这是一个很好的起点,因为当部件处于服务状态时,意外故障会带来更高的成本和时间影响。

常见的测试类型

该过程始于审查图纸或部分规范,以确定适当的测试方法,其可以包括:

模型生成和验证

旨在简化设计过程,组件和组件的实心建模以及有限元分析(FEA)是工程师的优质工具。机械测试的目的通常是生成这些FEA程序所需的数据,以生成初始组件模型。已经说,FEA模型不保证准确的结果,因此最实用的方法是:

- Develop a robust model from the materials testing data for the material

- 执行FEA以确定理论应力水平和位置,以及

- 使用产品资格测试或材料测试组件剪切(第一篇文章检查)以验证FEA模型。yabo娱乐vip

由于机械测试提供了经验数据,因此它可以用来返回并优化FEA模型。一旦实现了这一步骤,在模型中制定设计修改就会更容易,更可靠,而无需众多原型和测试迭代的增加的时间和成本。

拉伸试验

原材料批次易于变异,所以拉伸试验每批材料的厚度应确保其满足最低强度和延展性要求。尽管材料供应商有能力处理这些测试,但他们建议使用第三方实验室测试作为独立和额外的确认。确认原材料在可接受的范围内是防止未来问题的最简单和最具成本效益的保证之一。

Chemical analysis

Chemical analysis也essential for both material and product manufacturers as it identifies the contents and quality of materials used in manufacturing and product development. During the early stages of the product development process, it is essential to verify materials to avoid any in-service failures.

Hardness

生产后需要硬度测试,并且需要进行热处理以验证一致性。与拉伸测试一样,这是一种快速且廉价的测试选项,通常不需要最终部分进行破坏性测试。

疲劳试验

在大多数应用中,目标fatigue testing其目的是绘制一条疲劳强度曲线,以表征材料抵抗波动应力水平上的循环荷载的能力,或确定在部件寿命期内不会出现疲劳的工作条件。一旦建立了该曲线,将结果与零件设计标准进行比较,以确保材料能够使部件达到预期寿命。

The final part geometry can make it challenging to apply raw material fatigue data due to complex dimensional features such as notches and holes. When this is the case, it is recommended that the final part undergoes fatigue testing. Going a step beyond the previous methods discussed, this may require a more sophisticated test setup and include the destruction of some production parts. The upside to this approach is that not only can a fatigue strength curve be generated, but failure modes will be determined. This knowledge is valuable for design improvements and maintenance schedules.

疲劳和断裂力学

疲劳和断裂力学提供有关材料承受缺陷的能力以及对其强度的影响的数据。当涉及到制定维修计划和预测部件的使用寿命时,疲劳和断裂力学测试是一种非常流行的工具。一些机器部件在使用寿命内不可避免地会产生裂纹。更换零件成本太高,而且在许多情况下完全没有必要;关键是确定缺陷的严重性,并识别它何时越过界限成为关键问题。

疲劳和骨折力学由许多不同的静态和动态试验组成,这表征了一旦缺陷起源于裂缝裂纹骨折韧性的材料的抵抗力。这种情况如何在这种条件下如何做出反应,使工程师能够估计组件的生命。这意味着,在某些情况下,可以推迟昂贵的维修时间,方便安排工作。了解哪些材料具有更高的骨折韧yabo娱乐vip性可以改善设计和延长组分寿命。

压力破裂和蠕变测试

Stress rupture在整个产品生命周期也是必不可少的。它为工程师提供了关键信息,使他们能够通过深入了解材料和产品的长期压力影响来防止失败。yabo娱乐vip

测试是否值得投资?

As product testing often involves specialized test equipment, custom-fabricated fixtures, skilled test engineers, and additional products and materials devoted to testing, it requires organizations' investment. When today's competitive marketplace is taken into account, this investment can be difficult to justify when budgets are already squeezed at the start of the project. However, it cannot be underestimated that the failure to perform appropriate testing can have devastating consequences that can cost significantly more than the testing itself.

Here, we take a look at some of the actual costs that organizations face if they decide to forego testing:

Internal audit

避免测试的第一个也是成本最低的结果是通过内部审计或质量检查在内部发现不符合项。这并不是最坏的情况,因为产品还没有离开现场,这意味着损害是有限的。这种情况可以通过分离受影响的产品、评估合规性以及在必要时进行所需的返工来缓解。

审计失败

受到审计结果的影响是避免测试需求的更严重后果之一。在这一阶段发现的任何错误都可以纠正,因为受影响的产品可以召回和评估,并对重新发布的产品进行返工和修理。然而,除了时间和成本的影响外,组织还可能失去客户的信任和潜在的有价值的合同。

增加成本

如果利用缺乏准确的模型,产品和组件通常可以过度设计,使其更昂贵。使用适当的模型和基于经验测试数据的设计组件,可以减少创建组件的提前期。

产品故障

The most costly consequence of not testing is catastrophic product failure. The result of this can be devastating, ranging from product damage to loss of life, and the consequences are permanent with organizations exposed to legal prosecution.

放心,由于彻底的质量检查,产品衰竭很少发生。然而,这应该对职责是在项目和产品生命周期的每个阶段确保绝对产品一致性的优质工程师并不安慰。通过提供强大的内部测试能力并与认可的实验室合作,组织可以帮助确保每一步的连续性和质量。

努力防止未来的失败

Should products fail during the testing phase or in-service, failure analysis is a critical aspect of product development and system improvement, which helps us learn from the past, and helps prevent future failures.

Failure analysis is a multi-faceted, holistic approach to determine how and why a material or product failed. The initial stage of any investigation involves an in-depth discovery phase of the circumstances surrounding the failure and any relevant background information, including environmental factors, type of application, service life, and pertinent design information. Element's failure analysts then apply a wide variety of analytical methods and tools to inspect the failed part.

Based on the failure analysis process findings, Element experts provide recommendations and work closely with the customer to find solutions to problems for a diverse range of products and materials. The combination of our materials expertise and our knowledge of what impact the service environment can have on a material or product enables the rapid delivery of comprehensive results.

虽然确定任何故障的根本原因和相关责任是主要目标,但增加的价值是防止将来发生。

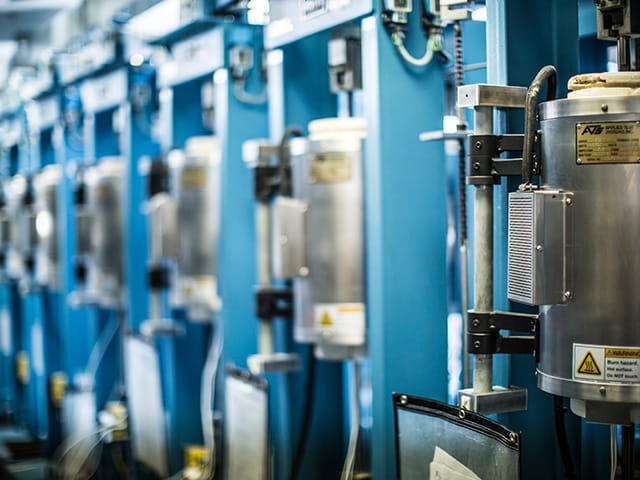

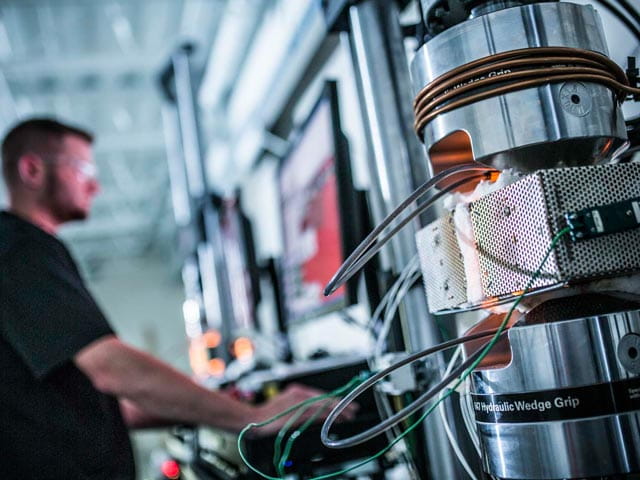

元素优势

元素为金属和非金属材料提供了一系列机械测试能力,以确保产品具有成本效益和技术先进,以及在整个生命周期中保持安全和适合的目的。yabo娱乐vip无论是测试到标准方法还是开发定制计划,我们的专家都可以为您提供大小的项目的准确,可靠的结果。有关更多信息,请联系我们的同事。

通过网站找到与您相关的文章Nucleus

获取我们专家的白皮书,文章,网络研讨会和活动邀请

订阅元素的资源亚慱体育怎么下载

making certain for nearly 190 years

更多来自元素

Three Steps to a Successful Vibration Test

Vibration testing is an essential step in determining how your product will operate in its intended environment. Make sure your test is the best it can be by following these steps.

Read More

航空航天机械试验

了解元素的拉伸,伸长,压缩,冲击,断裂韧性,应力,破裂,疲劳,硬度,磨损和磨损,弯曲,压力,剪切和扭矩检测服务。

Read More

聚合物机械测试

Find out about Elements unique range of mechanical testing services for polymers, elastomers, thermoplastics, composites and structural adhesives.

阅读更多

机械测试

元素's experts in materials testing labs across the US, UK, Netherlands, Germany, and Spain provide mechanical properties testing such as tensile, fatigue, fracture mechanics, and more.

Read More