What's the difference? EMC vs EMI

By Engaged Expert

Steve Hayes

Electromagnetic compatibility (EMC)andelectromagnetic interference (EMI)are frequently referred to when discussing the regulatory testing and compliance of electronic and electrical products. However, while they might be closely related, it is important to understand that EMC and EMI are not the same thing.

EMC vs EMI

EMI is the interference caused by an electromagnetic disturbance which affects the performance of a device. Sources of EMI can be environmental, such as electrical storms and solar radiation but more usually will be another electronic device or electrical system. If the interference is in the radio frequency spectrum it is also known as radio frequency interference or RFI.

EMC is a measure of a device's ability to operate as intended in its shared operating environment while, at the same time, not affecting the ability of other equipment within the same environment to operate as intended.

Electromagnetic compatibility and interference are extremely important design considerations. Failing to consider them in the early stages of product development can result in the time consuming and costly need to redesign the product at a later stage to meet EMC/EMI specification tests and prevent product failure or a safety risk.

Defining EMC or EMI

However, different requirements in the US and the European Union (EU), as well as differing interpretations of the meanings of EMC and EMI, often cause confusion when it comes to testing. In addition, specific industrial ormilitary standardswill apply to the product depending on its target market and therefore also need to be considered.

Evaluating how a device will react when exposed to electromagnetic energy is known as susceptibility or immunity testing and involves determining the ability of a device to tolerate noise from external sources.

Meanwhile, emissions testing measures the amount of EMI generated by the device that could affect other electrical products and can provide an accurate measurement of the amount and type of noise generated by a device. This is called an EMC level.

Determining which test to use

设备的应用程序将决定the exact type of testing required. Key questions to ask are:

- Where is this product going to be used?

- With whom is it going to interfere?

- How will the energy travel from the product to its “victim”?

The two key methods that electromagnetic activity or ‘energy’ can reach a product are through the air (radiation) or via the cabling (conduction). The standards used are therefore based primarily on radiated and conducted tests.

Good product design minimizes risk

If a product has to be redesigned, it can be prohibitively expensive and result in delays to market and a loss in consumer confidence. Bad product design (from an EMC or EMI perspective) would be when earthing, filtering and shielding have not been considered. The result of which would include product failure during test and in the real world would mean that the product would be unreliable and not work as intended. Good product design that incorporates the application of basicEMC principlessuch as effective shielding, earthing and filtering will simultaneously improve electromagnetic immunity and reduce electromagnetic emissions.

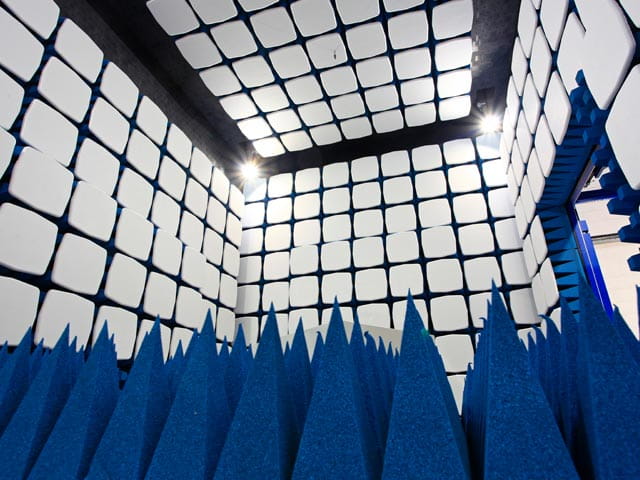

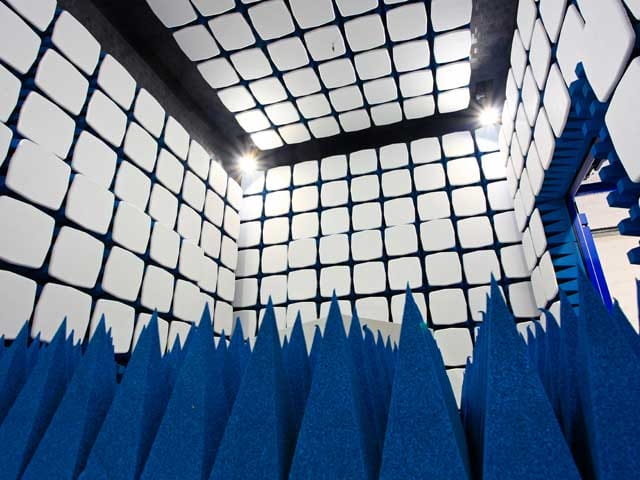

With excellent staff, ultra-modern facilities and automated test methodologies, Element offers the most efficient and accurate EMC and EMI testing available anywhere.元素的早期阶段资格(收®)service essentially makes sure that the shielding, filtering and earthing is properly considered early in the design process, supporting manufacturers through the complex nature of qualification testing.

Element provides access to testing laboratories on an hourly basis, as well as complete testing, reporting and certification services. For advice and support on EMC and EMI compliance or Element’s ESQ service, pleasecontact usor call UK +44 808 234 1667 or US +1 888 786 7555.

View more articles aboutMore Sectors

Find related articles to you through theNucleus

making certain for nearly 190 years

More from Element

Commercial EMC Testing

At Element, we test thousands of products every year, having one of the largest capacities for electromagnetic (EMC) testing of commercial and industrial electronic devices.

Read more

Advisory Services

Our team of Engaged Experts can help you understand the various regulatory requirements and reduce the test burden by comparing the various standards and producing compliance strategies that fulfill the brief of ‘test once, approve to many’.

Read more

Certification Services

Element has a dedicated team providing ISO 17065 accredited Certification Services from our offices across the globe.

Read more

Element Locations

Learn more about our laboratories - where they are located; the unique capabilities they have and how they can help you solve your technical and commercial challenges.

FIND A LABORATORY