Custom Load Monitoring for Multi-Specimen Medical Device Tests

As medical devices are being designed for use in new areas within the body, they may experience loading that is more complex than in traditional indications. For example, in the “old days” of coronary stent testing, we only needed to focus on generating a radial strain in the straight mock artery to simulate in vivo loading. Newer devices such as stented valves and grafts experience more complex loading.

The Challenge

An Abdominal Aortic Aneurysm (AAA) repair device may require a fixation means that sees a completely different type of load than the radial loading the tubular device geometry experiences. To simulate the different loading, a completely different test setup may be required. Likewise, new materials, material treatments and finishing may be used in a new device design, and a method for qualifying the new selections which does not involve full device fabrication is useful.

Oftentimes, a representative piece of the component such as a strut or sample coupon can be tested to rapidly determine the levels at which fatigue failure may occur. Furthermore, to obtain statistically significant sample sizes with a confidence level of 95% and a reliability of 90%, a minimum sample size of 29 is required. While an ideal scenario would be to test each specimen on its own individual tester, the use of 29 testers for one set of samples would be cost-prohibitive.

The Solution

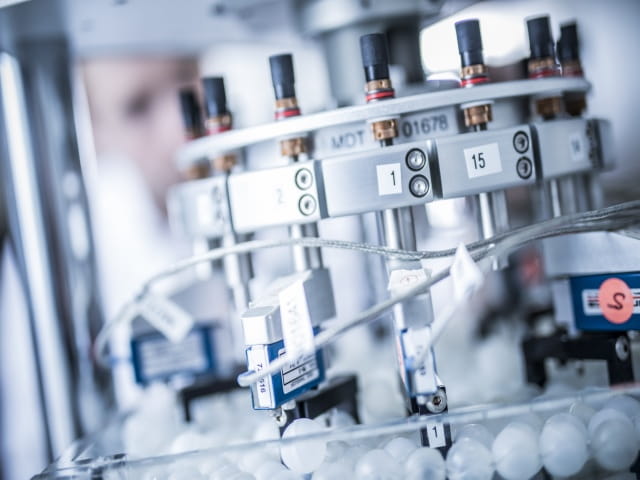

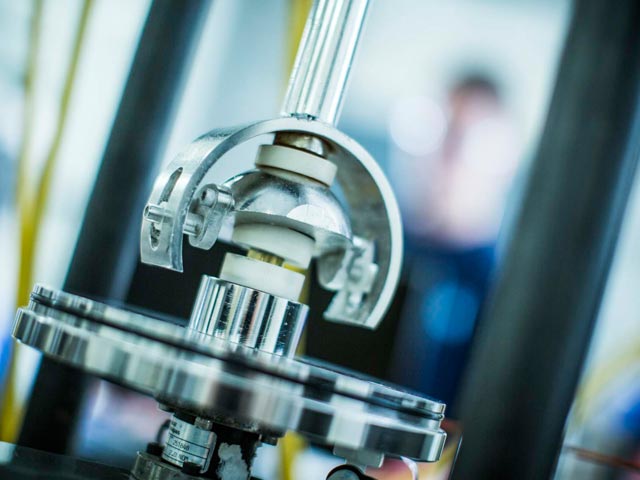

我们的“蜘蛛夹具”是对需要显着样品大小的多标本张力和压缩测试的全面解决方案。该固定装置包括具有信号调节器的单独称重传感器和集成到测试仪控制软件中的数据采集。这意味着每种样本的负载信号以及对样本的施加的位移获取。负载电池监测(Vs.没有负载监测)的优点是在整个测试中连续监测和记录施加的负载。各种样本负荷电池监测的一些主要益处包括:

- If a fatigue failure occurs, the cycle count is recorded so you know exactly the cycle count for each sample failure

- The tester can be set up to automatically stop so that visual or other examination of the failure can take place

- A new specimen can be installed to increase testing throughput.

- 个性化l sample properties can be obtained.

- Different mean loads can be entered.

元素的重大经验,使用多标本灯具和高吞吐量测试有助于识别潜在的陷阱以及如何避免它们。例如,我们开发了夹具设计,可通过夹具弯曲来最小化样本到采样的装载错误,并量化了这些误差。换句话说,并非所有多标本夹具设计都相同。

Another pitfall is the difficulty of removing and replacing specimens and getting them dialed back into the same loading. We accomplish this by providing an individual preload adjustment mechanism for each specimen. Several fixture configurations are available, and the selection of a particular configuration is dependent on the sample geometry and size. The sample number that can be accommodated is either 6, 12 or 15.

夹具包括定制样本夹具,可以调节各种长度的样本。该夹具设计用于模拟的生理环境中,例如37℃磷酸盐缓冲盐水。

Conclusion

The many benefits of multi-specimen testing have led the development of multi-specimen fixture designs for many different applications. Our engineers have significant experience working with high throughput testing and can help you avoid the pitfalls involved. After decades of experience testing many types of medical devices, Element experts have learned to adapt the various test instruments in our inventory to virtually any test application.

View more articles aboutMore Sectors

Find related articles to you through theNucleus