Element’s pipeline testing facilities perform fatigue testing on steel catenary risers in our laboratory and on-site at the point of fabrication. Our testing containers can quickly be mobilized to various locations, making Element both flexible and faster than any other testing provider on the market.

Offshore oil companies commonly employ Steel Catenary Risers (SCRs) as a means of connecting surface installations with subsea pipelines. Steel catenary risers are subject to harsh environmental conditions that include cyclic loading as a result of wind and wave motion, tidal flow, vortex-induced vibration (VIV), and operational changes to temperature and pressure. These conditions make welds, and other stress concentrating features, sensitive to fatigue cracking when in service. To mitigate against premature failure while in service, fabricators are often required to test the fatigue resistance of any proposed weld procedures before their use in SCR installations.

Weld fatigue testing

两种方法用于评估焊缝的疲劳敏感性;关于提取的优惠券的小规模测试,以及整个焊缝的全尺度测试:

- Small-scale testing,虽然更便宜,有几个限制。焊接的残余应力分布通过优惠券提取而改变,施加的应力曲线不是操作的代表性,并且它可以错过在原始焊缝中存在的应力敏感特征。

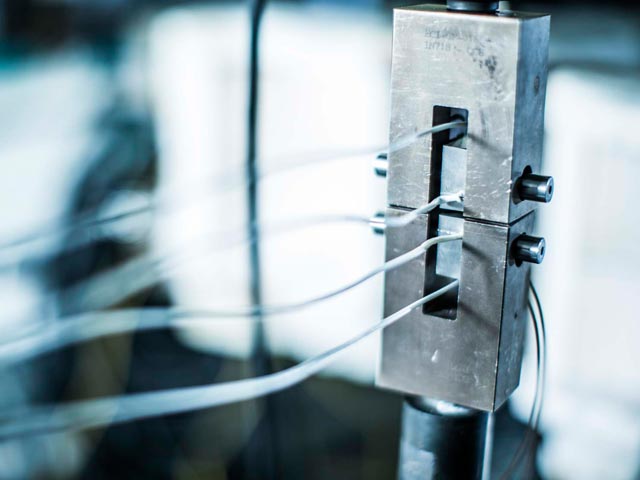

- Full-scale testing, conversely, allows the entire weld to be tested without alteration to its stress profile, using rotating bending stress that more accurately simulates the stress conditions seen in service. This stress can be applied by using large equipment to mechanical bend the welded pipe string, or by vibrating the test string near its natural resonant frequency (near resonance method). The advantage of this is that it can produce high-stress ranges in samples using relatively small, low powered vibratory motors. It tests the full 360 degrees of girth welds, and it can provide higher cycle frequencies (generally: 25-30 Hz), which speeds up testing.

Element’s mobile fatigue testing solutions

元素的原因ant fatigue testing rigs are fully integrated into modified shipping containers, making the rigs self-contained, modular, and mobile. Each container is equipped with its internal lifting system, and all equipment necessary to load, test and unload prepared test strings. The containerized design has several benefits over conventional lab-based models:

- It allows each rig to be移动, allowing for quick and easy mobilization between Element and Client sites.

- 它创造了一个intrinsic barrier通过限制访问和提高安全性的测试设备和人员之间,以及越来越多的运营商和现场员工的安全性。

- 它可以测试远程监控通过使用外部工作站和CCTV相机。

- Itremoves the need for overhead liftingduring sample loading due to the presence of integrated dual hoist systems.

- It allows the rigs to be located in uncovered areas outside of site buildings,freeing up valuable floor space.

To find out how our Oil and Gas experts can advise on weld fatigue testing on catenary risers, or to request a quote,联系我们today.

making certain for nearly 190 years

更多来自元素

Services

Corrosion Testing

Find out how Element's corrosion testing programs can drastically reduce the risks associated with corrosion.

READ MORE

services

Fracture Mechanics

Find out how Elements fracture mechanics services support the Oil and Gas Upstream sector

阅读更多

services

Engineering Critical Assessments

元素的完全集成工程关键评估服务对于减轻管道,压力容器,海上平台和工程结构的故障至关重要。

read more

Services

Coatings Testing

Find out about our Oil & Gas coatings testing services and how we help to make certain that materials, products and pipelines are protected from corrosion, ultraviolet light, water penetration, heat, abrasion and chemicals.

Read More